Boeing 737 and 757 Flap Transmission Test Stands

This test stand performs post overhaul testing of the trailing edge flap transmissions assemblies used on B737 and B757 aircraft. Each wing has 4 different transmission variations, one at either end of the both the inboard and outboard trailing edge flaps. The test stand is capable of testing all eight 737 wing station variants and two of the 757 station variants.

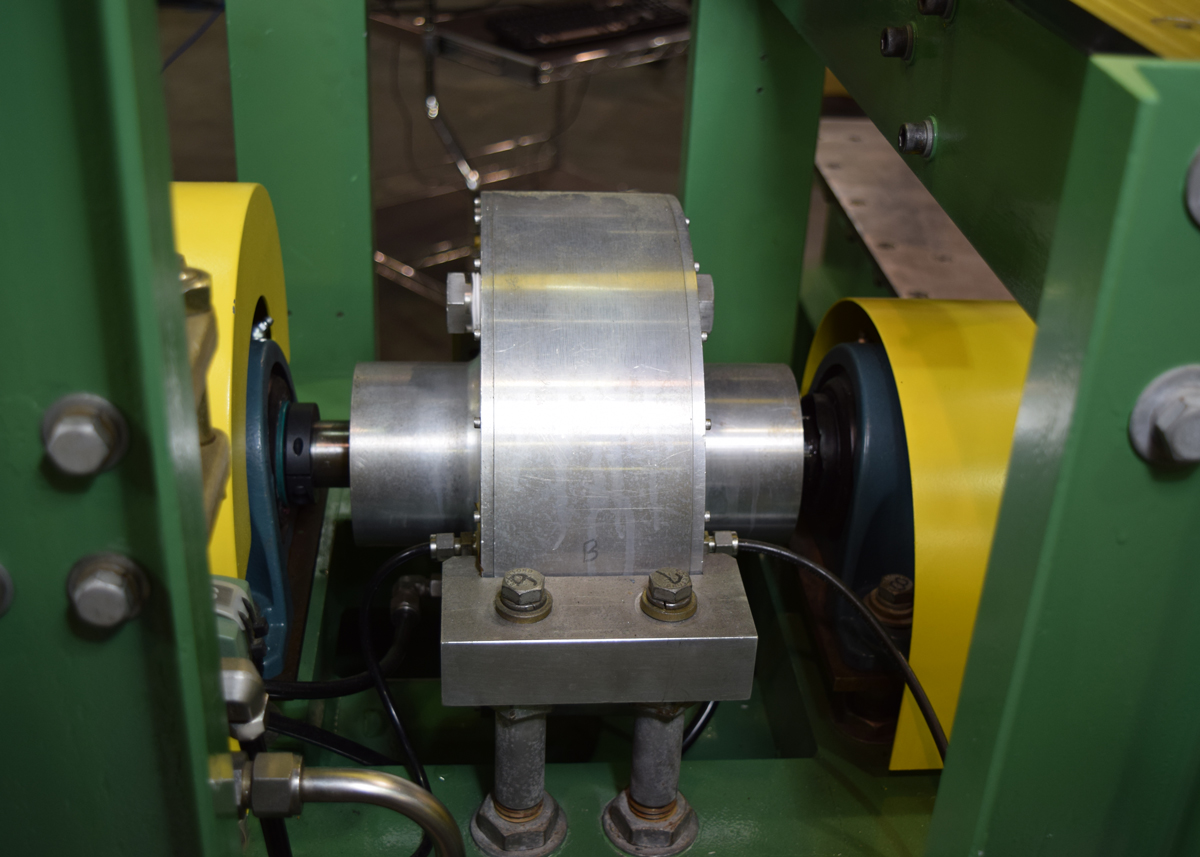

This flap transmission is a bevel geared assembly with an integral torque limiter and thrust bearing.

A VSD electric motor drives the output shaft while a pneumatically powered balance piston simulates flap ball screw thrust. A hydraulically powered gear motor drives the input torsion shaft while a disk brake provides a controlled torque ramp that tests the torque limiter actuation point. This hydraulic motor also provides the proof load to the torque limiter brake package.

All data such as torque, speed, lockup torque and mechanical efficiency are automatically recorded by the Opto 22 data system. A PC workstation provides the GUI.

Test procedures may be run automatically or may be done individually in semi-automatic mode. All required test reports generate automatically or on demand and feature pass/fail notification.

Aircraft applications:

Boeing B737-600/700/800 applications

| Part numbers: | CMM: |

|---|---|

| 256A3110 | 27-55-67 |

| 256A3210 | 27-55-68 |

| 256A3310 | 27-55-80 |

| 256A3410 | 27-55-70 |

Boeing B757-200/300 applications

| Part numbers: | CMM: |

|---|---|

| 251N4050 | 27-51-13 |

| 251N4022 | 27-51-13 |