Air Separation Module Test Stands

Military and commercial aircraft use on-board Air Separation Modules (ASMs) to produce nitrogen and oxygen enriched gas streams. Hollow fiber membranes of the ASM separate engine bleed air into the two gases. Nitrogen flows into the fuel tanks to reduce the risk of explosion from ballistic attack, lighting strikes or electrical static discharge. The oxygen enriched gas may be discarded or used for crew and passenger breathing air.

Emprise designs and builds custom turn-key test stands for evaluating ASM performance. Our test stands perform acceptance testing (ATP) on production units as well as providing post production and overhaul support of numerous aircraft. These include the military C-17 heavy lift aircraft, the KC-46 aerial refueling tanker, the Boeing 787 and 737, Mitsubishi Regional Jet, and Airbus A320 commercial aircraft. Additional ASM units may be easily added.

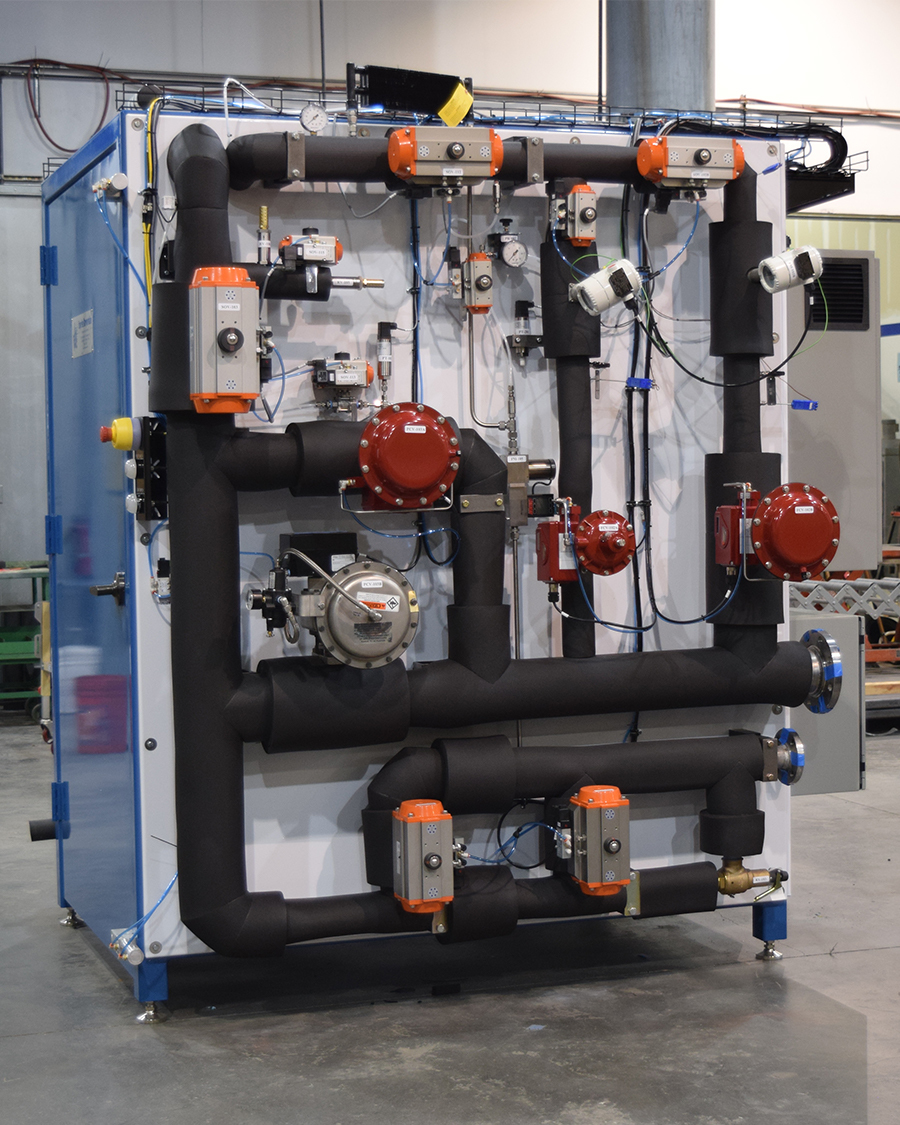

The ASM Test Stand consists of a protective enclosure with process piping systems, control instrumentation, and data acquisition system mounted to exterior walls for easy maintenance accessibility. A desktop computer (PC) serves as the operator interface. An Ethernet cable connects the PC to the data acquisition and control hardware allowing simple and flexible test stand usage. A LabVIEW application runs fully automated test sequences that may be customized according to the customer’s test procedures. Standard tests include Leak Test, Proof Pressure Tests, Gas Performance Tests, and a 15-point Sample Test. Multiple sequences may be run automatically back to back.

The test stand precisely controls the inlet air stream to simulate bleed air conditions at various aircraft altitudes. ASM air temperature, NEA (nitrogen enriched air) flow, and Permeate (exhaust) pressure conditions may be specified within definable tolerances and are continuously monitored. Once all test conditions are obtained, the percentage of oxygen in the NEA flow is measured. Automatic Pass/Fail checks are performed at this point. Test conditions are recorded and placed in a report once all conditions remain in tolerances and the O2 percentage remains within tolerance for a definable time period. The printable report uses a template that is in Excel format.

Periodic, time stamped data logging to disk may be requested by the test stand operator.

Test conditions reside in a database that can be modified by the client’s engineer with the required password and access level.