Anemometers

If you like our anemometers, you’ll love our test stands – let us help with your other testing products and services!

Test Facilities | Test Stands | Portable Test Cells | Services

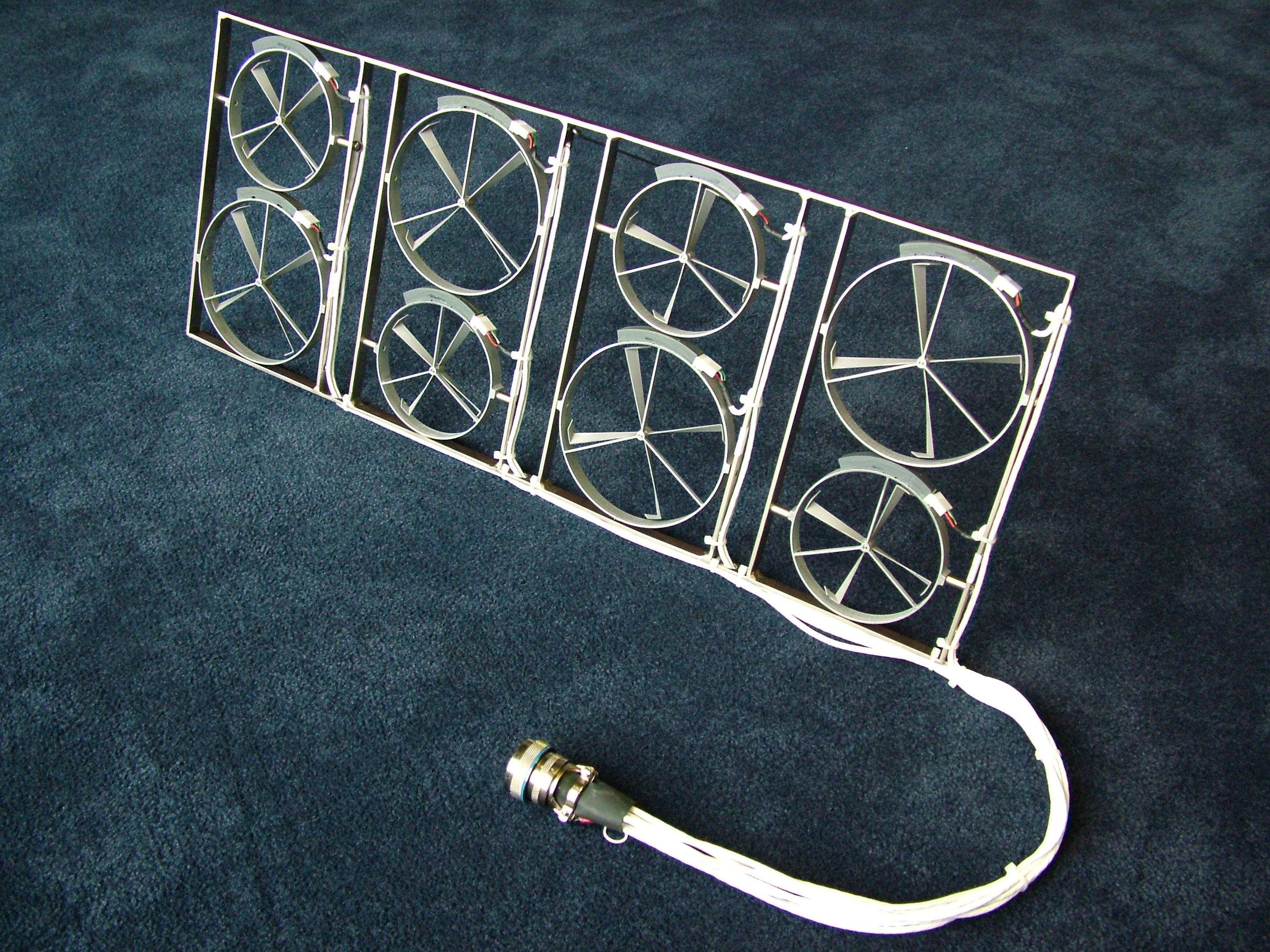

The Emprise anemometer was originally developed in 1985 for mapping airflow of heat exchangers during vehicle wind tunnel testing. Initial development was carried out at the Lockheed-Martin Low Speed Wind Tunnel.

Over the past 30 years the Emprise anemometer has evolved into a precise and rugged instrument used in the automotive and aerospace industries as well as race teams over the world. The design has proven ideally suited for a variety of air flow measurement applications including radiators, condensers, intercoolers and other heat exchangers, vehicle and building ventilation (HVAC) ducts, cabin airflow, engine compartment airflow, intake manifolds, brake cooling ducts, wind tunnels and under vehicle airflow. Whenever an accurate and wide-ranging flow measurement is required, Emprise turbine anemometers will provide years of reliable service.

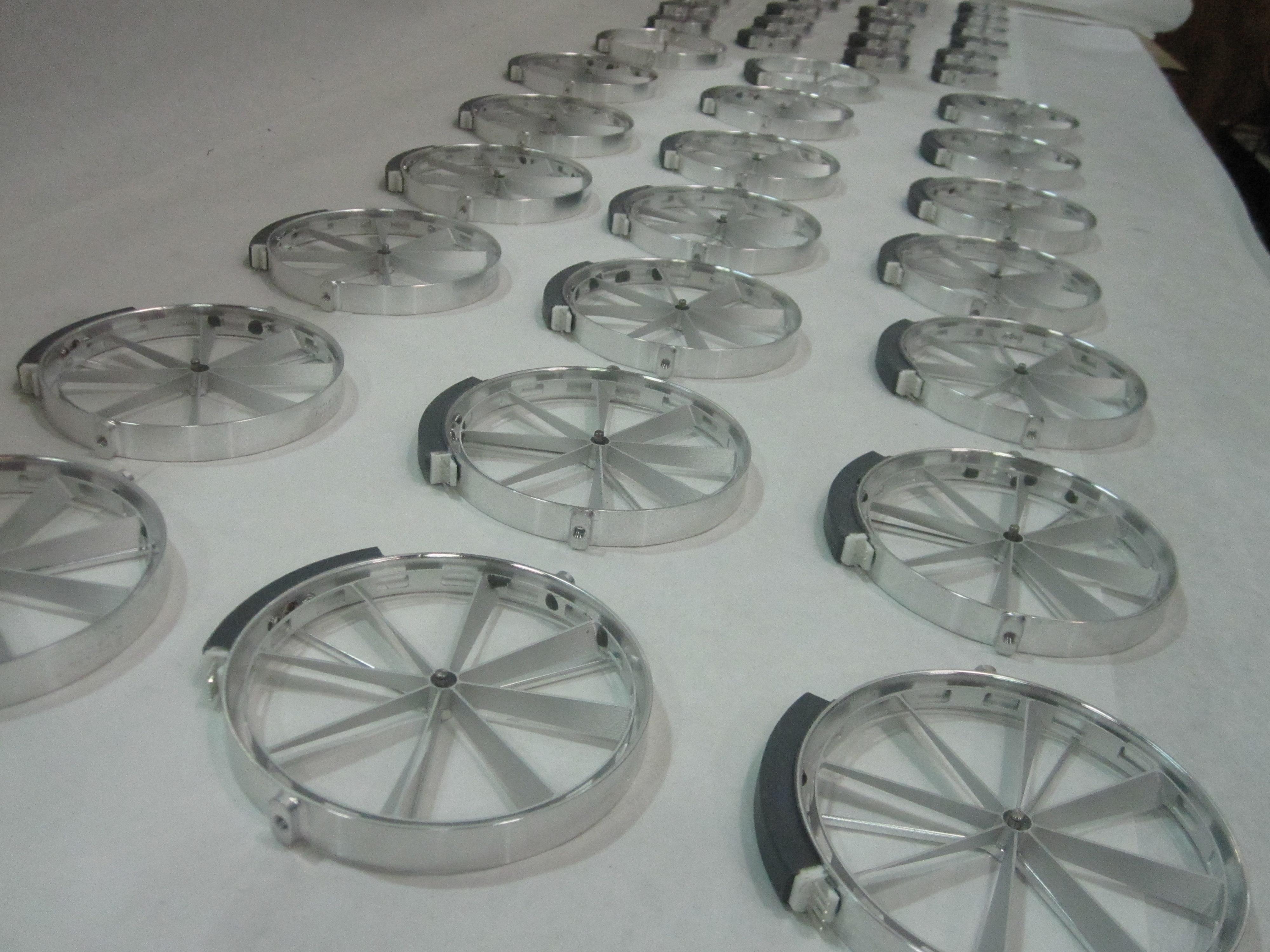

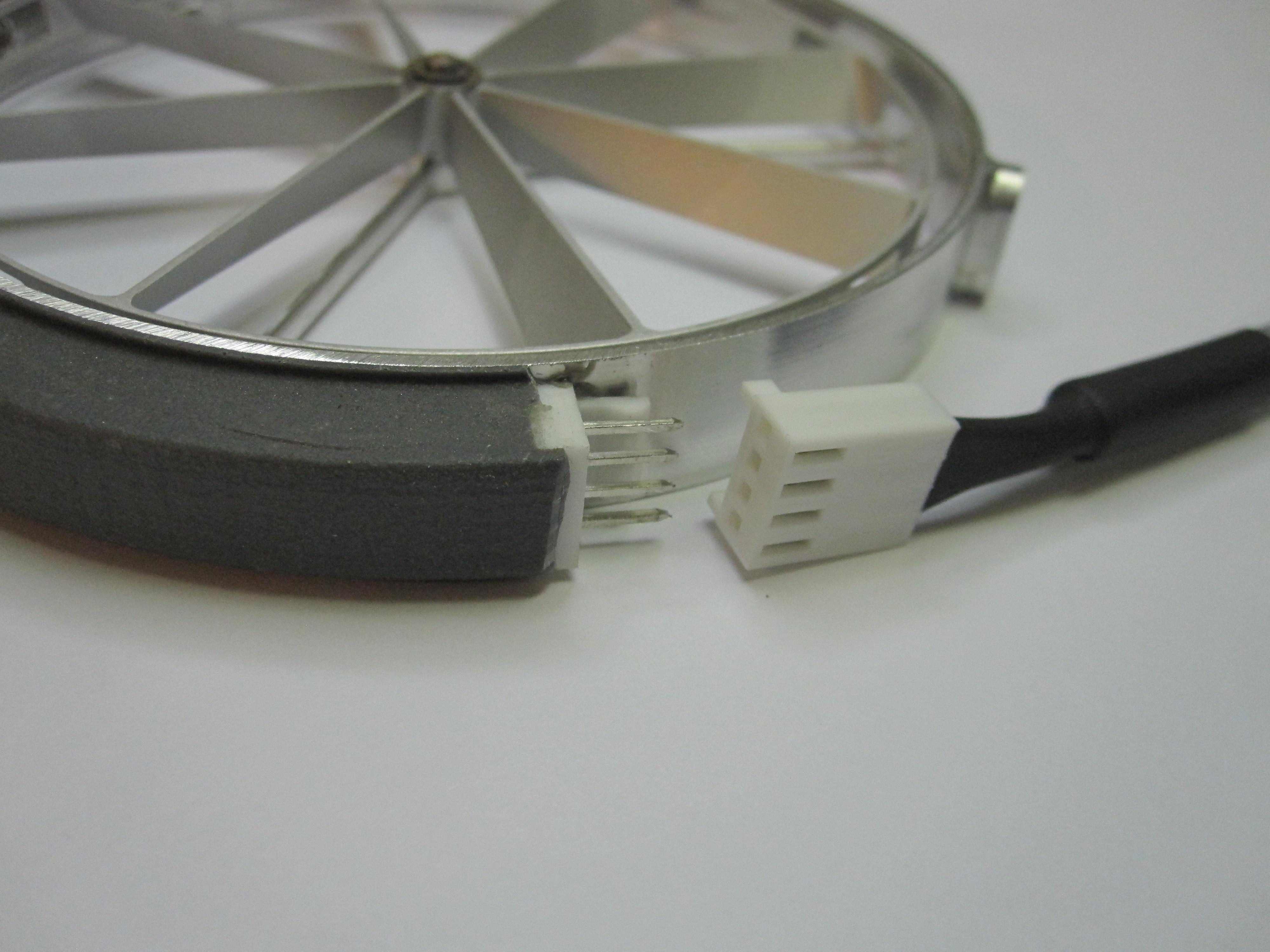

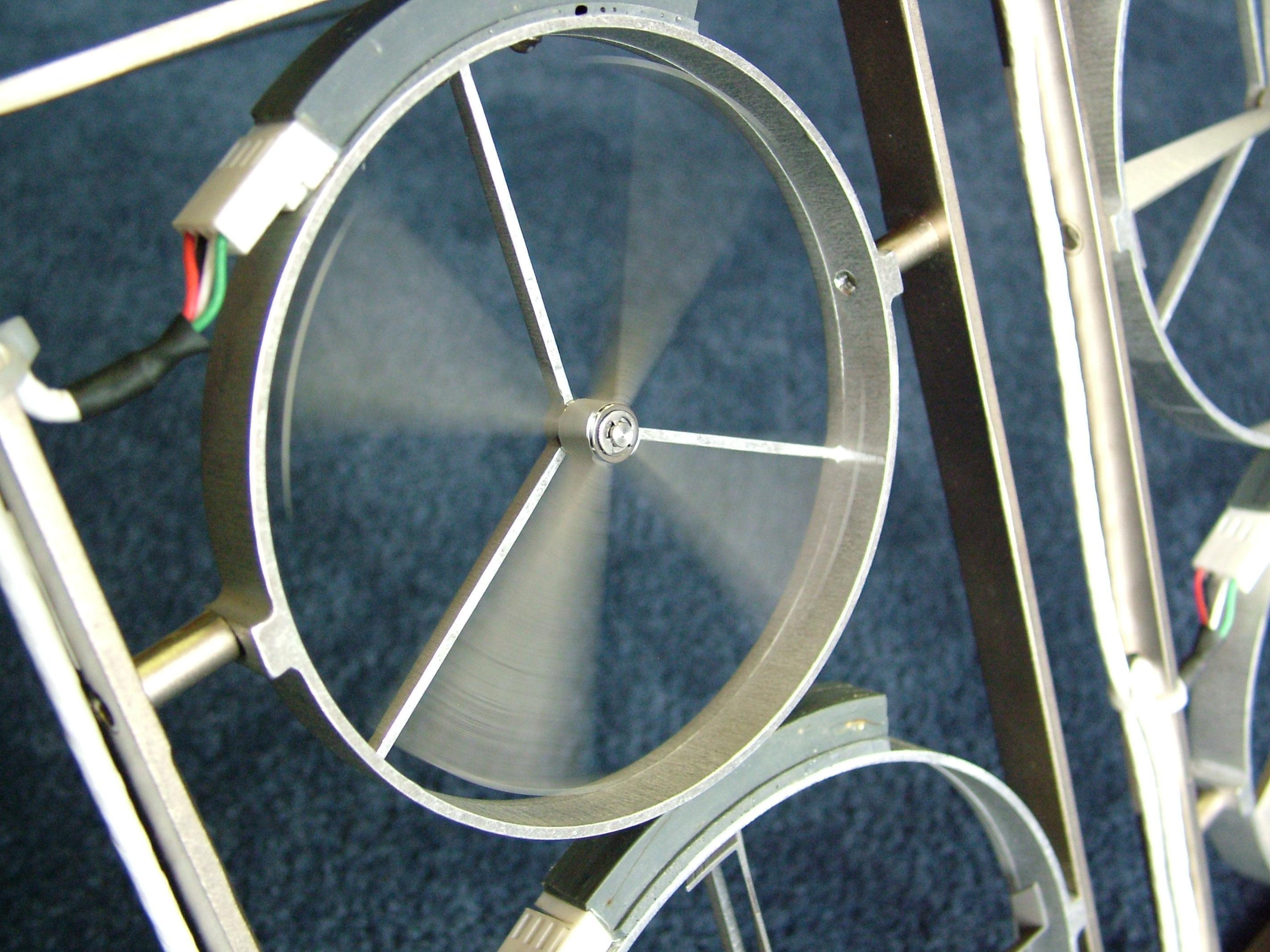

The Emprise anemometer uses a helical turbine to measure air velocity. As air passes through the anemometer, the turbine blade rotates at a speed proportional to the air velocity. Turbine speed is sensed by infrared sensors which output a TTL square wave signal at a frequency proportional to speed. The sensors also output a digital bit to indicate the direction of flow. The anemometer turbine and support ring are machined from aluminum alloy billet using an extremely accurate 3D CNC machining process. The turbine blade rotates on high precision ABEC 5 bearings that are easily replaceable if they become damaged or contaminated.

Advantages of Emprise Anemometers

Better overall accuracy

Turbine anemometers measure the average velocity over the area swept by the turbine. This yields better overall accuracy when compared to pinpoint measurements made with “hot wire” thermal type anemometers or differential pressure “pitot” probes.

Reverse flow detection

Emprise anemometers include circuitry to detect reverse turbine rotation indicating reverse airflow.

Simple, rugged design

Emprise anemometers can withstand the harsh conditions of race car testing and provide high levels of precision over a wide range of measurement.

Anemometer Specifications

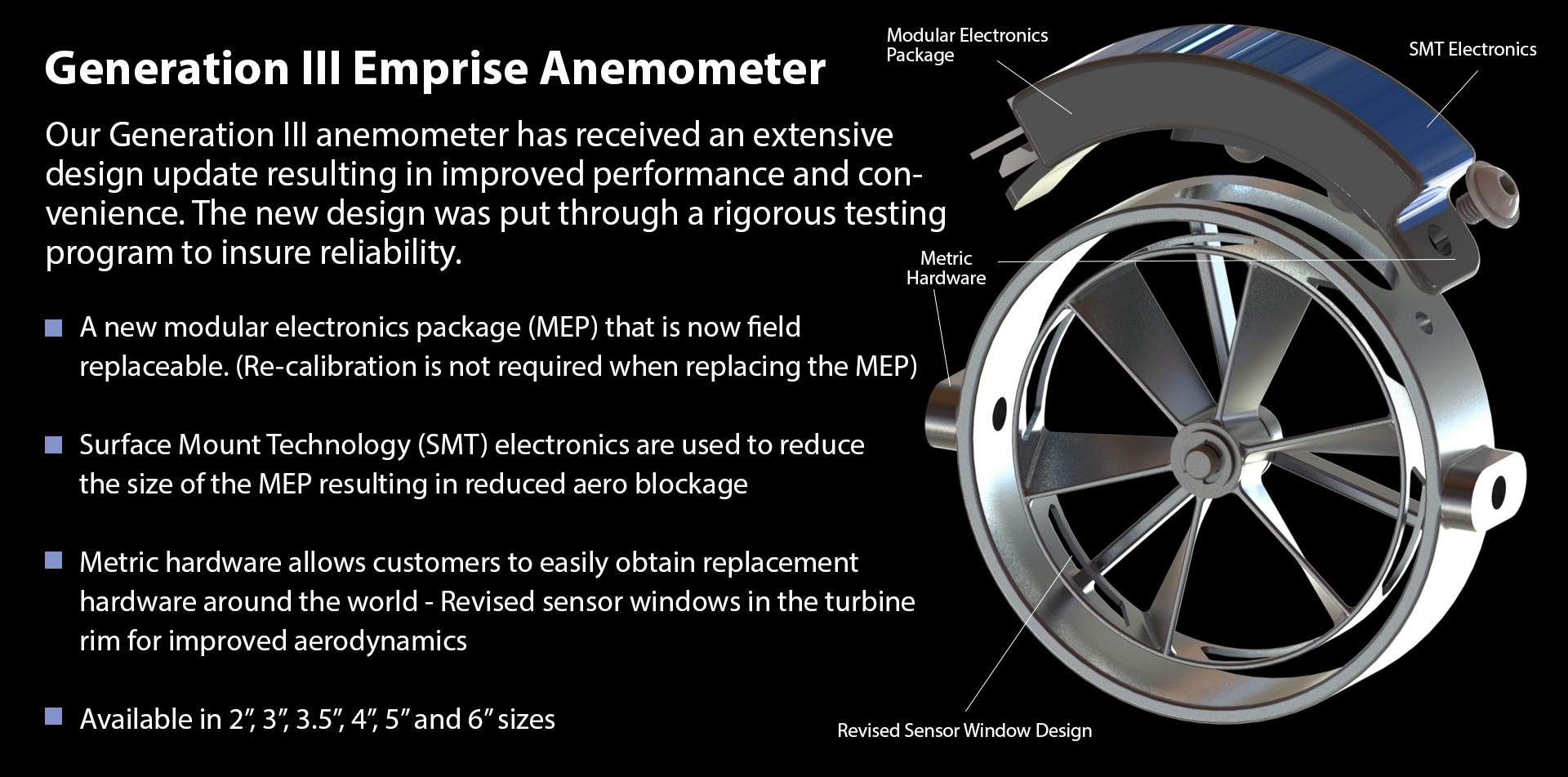

- Standard sizes: 2”, 3”, 3.5”, 4”, 5” (50, 75, 90, 100, 125mm) support ring O.D.

- New 6" size

- Total thickness: 0.500” (12.7mm)

- Excitation power: 8-14 VDC, 100 mA typical

- Anemometer output signals:

- Speed: TTL level square wave, frequency proportional to speed

- Resolution: 6, 12 or 16 pulse/rev depending on size

- Analog speed signal available with signal conditioner [button to signal conditioner page]

- Direction: 5 Vdc discrete bit (high when air is coming from strut side)

- Materials: aluminum alloy, stainless steel

- Enhanced calibration algorithms for improved low speed accuracy

- Bearings: ABEC 5

- Mounting: Two M4x0.7 tapped holes provided

- Operating temperature: -40 to 250°F (-40 to 121°C)

- Calibrated velocity range: 5 to 90 ft/s (1.5 to 27 m/s)

- Maximum velocity: 175 ft/s (120 mph) (53 m/s) (192km/hr)

- Signal Conditioning Units available

- Custom Data Acquisitions Systems available